A focused factory is a permanent facility to produce a product or component in a product-oriented facility.

Example: A job shop with machinery and personnel rearranged to produce 300 unique control panels. Example: Pipe bracket manufacturing at a shipyard.

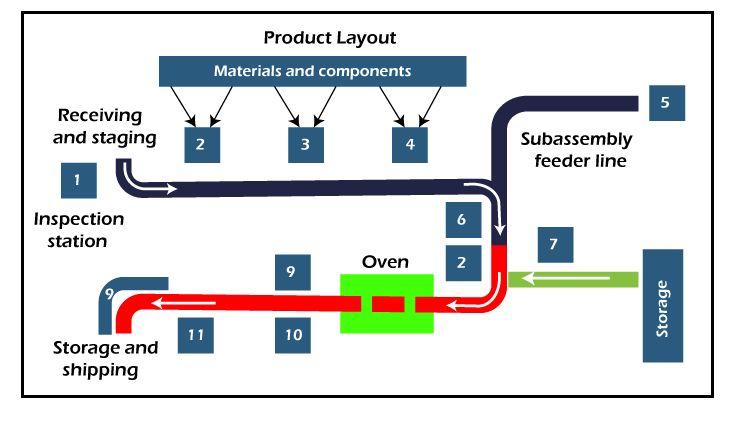

Staffing Work Cells Example 600 Mirrors per day required Mirror production scheduled for 8 hours per day From a work balance chart total operation time = 140 seconds Standard time required Operations Assemble Paint Test Label Pack for shipment 60 50 40 30 20 10 0.Staffing and Balancing Work Cells Determine the takt time Takt time = total work time available units required Determine the number of operators required Workers required = total operation time required takt time.Figure 9.10 (b) U-shaped line may reduce employee movement and space requirements while enhancing communication, reducing the number of workers, and facilitating inspection Improving Layouts Using Work Cells Current layout - straight lines make it hard to balance tasks because work may not be divided evenly Improved layout - in U shape, workers have better access.Process Layout Example Receiving Shipping Testing Department Department Department (4) (5) (6) Figure 9.8 Painting Assembly Machine Shop Department Department Department (2) (1) (3) Room 1 Room 2 Room 3 Room 4 Room 5 Room 6 60’ 40’.Process Layout Example Interdepartmental Flow Graph Figure 9.7 30 50 10 50 50 20 50 100 100 2 1 3 4 5 6.Process Layout Example Interdepartmental Flow Graph Figure 9.6 100 50 20 50 50 20 10 100 30 1 2 3 4 5 6.Process Layout Example Receiving Shipping Testing Department Department Department (4) (5) (6) Figure 9.5 Assembly Painting Machine Shop Department Department Department (1) (2) (3) Room 1 Room 2 Room 3 Room 4 Room 5 Room 6 60’ 40’.Process Layout Example 50 100 0 0 20 30 50 10 0 20 0 100 50 0 0 Figure 9.4 Department Assembly Painting Machine Receiving Shipping Testing (1) (2) Shop (3) (4) (5) (6) Assembly (1) Painting (2) Machine Shop (3) Receiving (4) Shipping (5) Testing (6) Number of loads per week.Process-Oriented Layout where n = total number of work centers or departments i, j = individual departments X ij = number of loads moved from department i to department j C ij = cost to move a load between department i and department j Minimize cost = ∑ ∑ X ij C ij n i = 1 n j = 1.Process-Oriented Layout Figure 9.3 Surgery Radiology ER triage room ER Beds Pharmacy Emergency room admissions Billing/exit Laboratories Patient A - broken leg Patient B - erratic heart pacemaker.Alternative Strategy As much of the project as possible is completed off-site in a product-oriented facility This can significantly improve efficiency but is only possible when multiple similar units need to be created.

Relationship Chart Figure 9.1 Not desirable X Unimportant U Ordinary OK O Important I Especially important E Absolutely necessary A Closeness Value President Chief Technology Officer Engineer’s area Secretary Office entrance Central files Equipment cabinet Photocopy equipment Storage room O U A X O U A I O A I O U A I I A U O A U O U X O I U O I I I E E E E E 1 2 3 4 5 6 7 8 9.Strategic Importance of Layout Decisions The objective of layout strategy is to develop an economic layout that will meet the firm’s competitive requirements.

0 kommentar(er)

0 kommentar(er)